Robot Drivetrain

A robot drivetrain is the most fundamental robot subsystem. The drivetrain commonly refers to the robot frame configuration, the drive system, and the power transmission system (including gearboxes, belt, or chain).

Contents

Importance and Fundamental Considerations

The drivetrain is the single most important component of a winning robot. Good drivetrains are built robustly, are easily repaired, are built within the resources of the team, and are tailored to meet strategy goals. A good drivetrain may be one which can be adapted for more than one design, such as in the case our 2013 robot, Orangahang (also known as Mk. II and Mk. III). Optimally, the drivetrain should be able to be fixed within 4 minutes, as this is the longest allowable timeout that a team can call before a match.

When designing a drivetrain, it is crucial to understand your team's resources. The first is cost. How much can the team afford to spend on this subsystem? The robot budget must include manipulators, drive station pieces, and other components. While a drivetrain is the most important part of the robot, we must be aware that it isn't the only part. The more complex the drivetrain design is, the more time and money it will take to perfect. When in doubt, keep the design as simple as possible (KISS). A simpler design is quicker to design and build, faster to get up and running, easier to fix in an emergency, and easier to maintain for future years. During build season, time is everything. Getting the robot driving early will allow the team time to discover and fix the design's shortcomings. It will allow drivers time to practice, and also give the team more time to fine-tune its performance. Don't forget the electronics and software teams!! They also need time to configure the drivetrain before it can be effective.

Drivetrain Characteristics

Deciding the type of drivetrain is crucial to accomplish early. It depends on team strategic focus for that years game, which needs to be decided as quickly as possible following kickoff. Attributes of a robot drivetrain which can aid in effectively implementing a strategy might include:

- Speed

- Power

- Pushing force

- Climbing

- Maneuverability

- Acceleration

- Accuracy

- Obstacle handling

- Reliability

- Durability

- Ease of control

- Available team resources

It's important to realize that we have to sacrifice some attributes for others. No single system will perform all of the above functions. As with every engineering decision, we must weigh the pros and cons of each design aspect.

High Speed

Drive systems with a high top speed might employ the following features:

- High power output

- High efficiency

- Optimized gearing ratios

Robot designs optimized for speed obviously require an open playing field to be effective. The 2008 game, Overdrive, provides an excellent example of a challenge where speed won regionals. In 2013, Ultimate Ascent saw fast robots reduce their cycle times and contribute to their alliance score very efficiently.

Acceleration

- High power output

- Low inertia

- Low mass

- Optimal gear ratio

The single most important factor in designing a robot which can accelerate quickly is the robot's mass. It requires significantly more force to accelerate a heavy robot, which we know from Newton's Second Law: F=ma. An accelerating robot would perform well for games with a divided or confined field, where speed is important but there is not enough room to attain high velocity. Look to Rebound Rumble(2012) and Logomotion(2011) for examples of challenges where acceleration was important.

Pushing/Pulling force

- High power

- High traction

- High efficiency

- Proper gearing

When designing a robot for a defensive role, pushing force is almost always a desirable trait. Pushing or pulling is often a question of traction and power output. Almost every year provides an opportunity to push against other robots while playing defensively. In 2009, Lunacy required robots to tow trailers on a traction-limited field, and being able to put power down without slipping was crucial.

Obstacle Handling and Climbing

- Ground clearance

- Obstacle protection

- High traction

- Drive wheels on the ground

2015, Stronghold, provides the best example of a challenge in which obstacle handling mattered. Robot drivetrains were required to mount challenging obstacles to traverse the field and score points. Ground clearance mattered much, as did protecting from collisions and hard landings (using skid plates and reinforced hardware). It's important to design an obstacle handling robot so that it can have wheels in contact with the ground at all times, so that it does not risk getting high centered or being unable to drive over an obstacle. Again, traction matters more than anything else. In 2012, Rebound Rumble required robots to either climb ramps or drive over a low dividing wall which split the field in two. Many robots didn't have enough traction on the slicker ramp surface, and weren't able to effectively drive up a ramp or balance on one for points.

Accuracy and ease of control

- Good control calibration

- Proper gearing

- Intuitive control

- High reliability

- Reduces friction

To ensure that a robot can be drive accurately and precisely, it's crucial to make sure the electronics and programming teams can have enough time with the system. Installing sensors and writing better code means that in the end, the driver can be more consistent and the robot will succeed in its planned role. What good is a drivetrain if it cannot be controlled?

Reliability and Durability

- Simple

- Robust

- Good fastening systems

Simplicity and robustness are desirable characteristics for a drivetrain focused on reliability. Simple systems are easy to fix, and robust ones tend not to. In Stronghold, it was relatively common for broken chains, batteries, nuts, and bolts to litter the field after a rough match. Finicky drive systems suffered. Simple ones which could withstand repeated impacts thrived.

Maneuverability

- Good turning method

- Low friction

- Refined controls

Maneuverability often greatly aids offensive robots in dodging defenders or maneuvering through tight spaces. Omnidirectional drivetrains, while difficult to design and built, usually increase their team's scoring potential by huge margins. With the increased maneuverability also comes an inherent difficulty in controlling the robot. Refining the control scheme and its accuracy is crucial.

Drivetrain Layouts

General Drive Base Properties

Usually, drive bases which are wider than they are tall will have faster turning times and be more maneuverable, whereas ones which are taller than they are wide will inherently track straighter but suffer reduced turning ability. In both of these cases, this affects the driver's control of the robot. The greater the distance between a wheel's contact patch and the robot's turning center, the faster it will turn the robot as a whole. Choosing the orientation of the robot chassis is a critical design decision which must be one of the initial considerations. Ask strategic questions, such as "do we need to mount obstacles?" or "is turning rapidly important to our goals?" to help decide this choice. Also consider the physical space on the field: sometimes there are areas which constrict the width of a robot trying to pass through it.

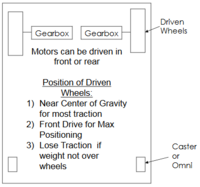

2 Wheel Drive

There are many advantages to a two wheel driven system. It's easy to design one, easier to build it, typically very lightweight, and often inexpensive. As an added benefit, they are often agile, turn quickly, accelerate fast, and have a high top speed. This drive system is very easy to build with COTS (commercial off-the-shelf) components.

There are drawbacks, however. The power output from two driven wheels is quite low, and the robot can suffer a lack of traction (especially when trying to climb ramps or obstacles). Due to the poor traction of the design, the robot can't push well and is easy for a defender to push from the side. They can be hard to control and and have a susceptibility to spinning out. Great for showing off and doing donuts, but not as great in a match.

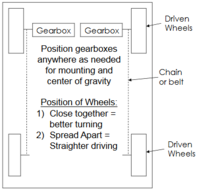

4 Wheel Drive (Tank Drive)

Four wheel drive systems are also easy to design and build, but they have more power output. They are very sturdy and stable drivetrain layouts, and can work well with nearly any wheel choice, including omniwheels, traction wheels, pneumatic wheels and others. A four wheel driven robot can be fabricated using COTS components, making this another popular choice for newer teams looking to keep it simple.

However, 4 wheel tank drive is not a particularly agile configuration. Due to the long wheel distance to the turning center of the robot, lots of friction is introduced into the system while turning. Special adjustment is usually needed for turning, such as modifying the frame or adding low-friction wheels such as omnis or ball casters. This drive base usually weighs more than a two wheel system, contributing to lower acceleration and top speed. Since each side of the robot must be driven, chain or belt is a requirement, whereas the two wheeled system could drive wheels directly with motor or gearbox shaft output.

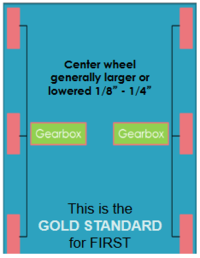

6 Wheel Drive

Six wheel tank drive is the gold standard of FRC drivetrains. It is a proven, reliable design which many teams can build. It provides a large contact patch and high traction with a high power output. It is an inherently stable design, and can be very agile if designed correctly. Turns are based around the center of the robot, aiding with control and turning speed. Because of the increased traction, a six or n-wheel drivetrain is ideal for pushing and defensive robots. It is very difficult for a six wheel robot to become high-centered. The system may be build using existing designs and COTS components. The AndyMark KOP Drivetrain is a six-wheeled layout.

The drawbacks of the six wheel configuration usually include the added financial burden of a larger, more complicated system (wheels alone are expensive!), and that it is inherently a very heavy robot base. With added wheels, there is greater traction, but with this comes the introduction of a large amount of turning friction, which is undesirable. Routing chains to drive each wheel can sometimes be a difficult design task.

There are several ways to make a six wheel drivetrain more agile, and all are methods of reducing the robot's turning friction.

- Lower the axle of the center wheel, dropping the contact point of the middle wheels by a small amount, usually 1/8th of an inch. This is commonly referred to as a West Coast drive, and is implemented by the KOP drivetrain and many team's designs. By ensuring a small difference between the depth of the center wheel and the others, the instability of the robot can be managed. Larger drops often mean lots of rocking when accelerating the robot forward and backwards. Regardless of the drop amount, rocking is magnified at the ends of the robot, which is very important to consider if the design includes manipulators near the frame perimeter. Essentially, a West Coast drive aims to reduce turning friction by slightly lifting two wheels off the ground.

- Adding omniwheels on the front, back, or both axles. Omniwheels greatly reduce side-to-side dragging friction due to their design, which allow the robot to turn more easily. With this solution comes the usual drawbacks of omniwheels, including reduced pushing resilience, loss of robustness, and reduced straight-tracking due to loss of traction.

Treads (True Tank Drive)

Tank-style treading is an uncommon drive choice, but in some designs can be greatly useful. Stronghold, for example, saw the successful use of many tank-treaded robots. Treads provide unparalleled climbing ability and a very high amount of traction. They can push nearly anything while remaining very stable. There is a very large contact patch, and as such a high power output. Turns are about the center of the robot, aiding in driver control. Treads are newly available as a COTS component (Andymark Rhino Tread module).

There are huge drawbacks to treads. They suffer from high weight, low energy efficiency and a high level of mechanical complexity. They aren't easy to design, build, or fix, so they usually aren't a good choice for student teams. Friction, especially turning friction, is very high. Motors can easily stall or burn out. So much friction is introduced when turning, in fact, that treads can be ripped off of the robot during driving from turning friction alone. Whether using a COTS or custom design, treads will be an expensive option.

Omnidirectional Drives

"Omnidirectional motion is useless in a drag race, but pretty great when you're in a minefield."

-Overheard at FIRST Championship

Task and strategy determine the usefulness of an omnidirectional drive system. Remember, such systems are mechanically and programmatically complex, and should be evaluated carefully at the strategic level.

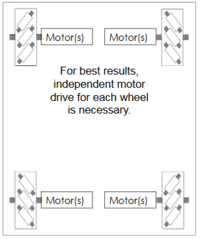

For all omnidirectional drivetrains, there is a huge step up in the programming complexity of the controls. However, the marginal difficulty (from a programming standpoint) is often small between different omnidirectional drives. Omnidirectional drives usually require independently driven wheels, so uneven weight distribution on the wheels can cause unequal amounts of traction on each wheel. This results in drift, where the robot can move in paths which are different from its control inputs. Drift reduces the precision and reliability of a drivetrain, and is perhaps the most difficult problem to combat when designing an omnidirectional system.

Control of an omnidirectional drive requires understanding a fair bit of vector math.

Mecanum

Main article: mecanum drive

A mecanum drive uses mecanum wheels to obtain omnidirectional motion. By changing the direction and speed of each wheel's rotation, the robot can drive forward and backwards, strafe side to side, or turn about the center of the robot. The mechanism itself is fairly simple, grants high maneuverability, immediate turning, simpler control compared to other omnidirectional systems, simple transmission of motor torque, turning about the center of the robot, and COTS availability.

Drawbacks of mecanum use include lack of braking power (the robot will slide to a stop), reduced pushing ability, difficulty with inclines, software complexity, expense, and drift. Each motor must be independently driven, which requires independent gearboxes and increased weight.

Holonomic

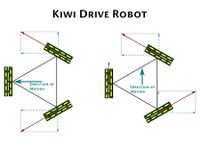

Holonomic drive horizontally opposes 3 or 4 omniwheels, and uses vector addition to properly control the robot.

Holonomic drives turn very quickly about the center of the robot and have a fairly simple steering method. They are quite maneuverable, and is the first omnidirectional drivetrain we have examined that truly has the ability to move in any direction.

However, they require 3-4 independently driven motors, contributing to added weight and cost. There still exists a need for advanced programming. Holonomics have no braking ability whatsoever, and cannot climb ramps. They cannot push. Drift is a major issue.

Swerve and Crab

Main article: swerve drive

Swerve drive is the truest omnidirectional drivetrain, providing degrees of freedom in every horizontal direction. Swerve drives are controlled by independently steered and powered wheels.